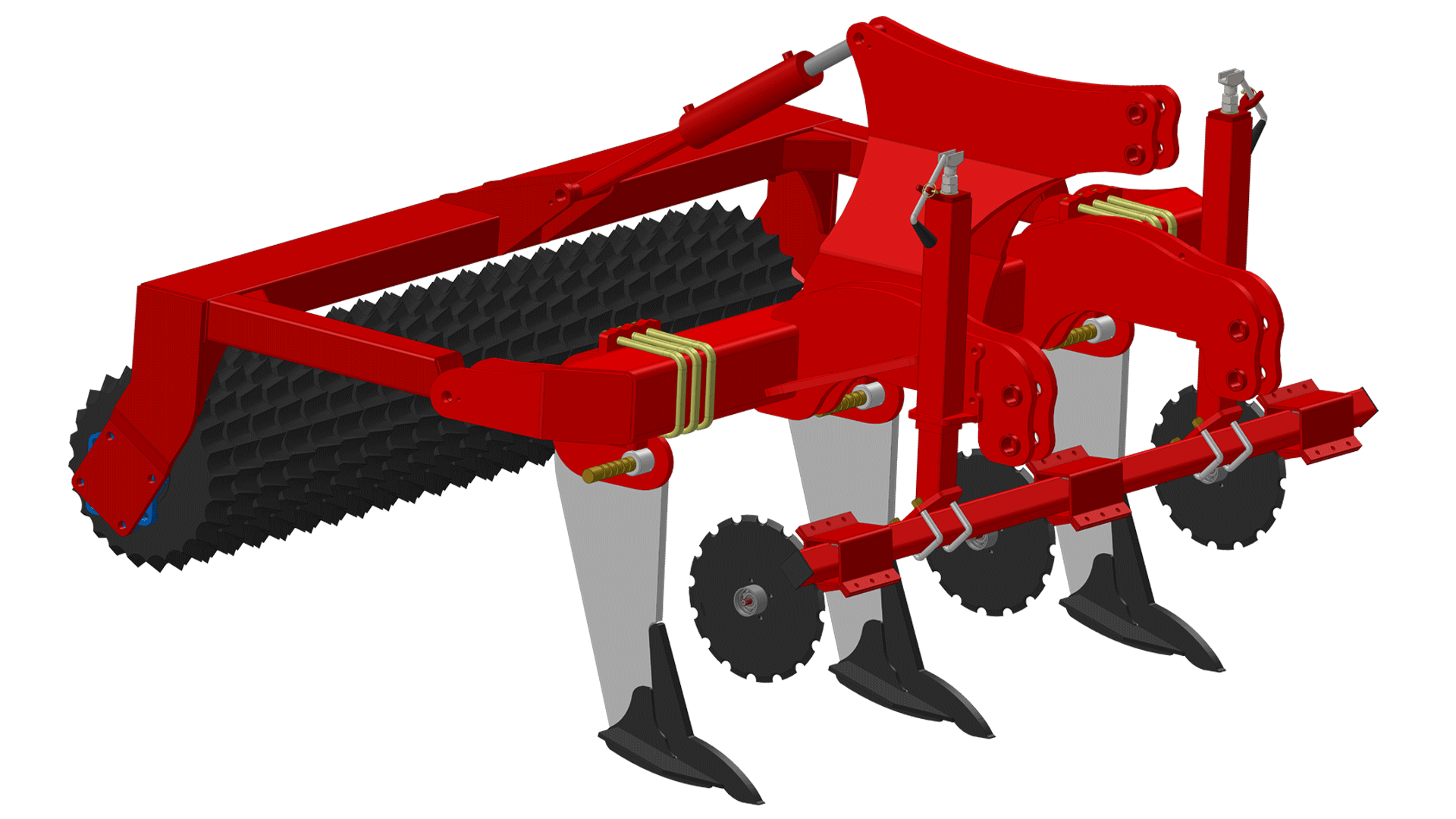

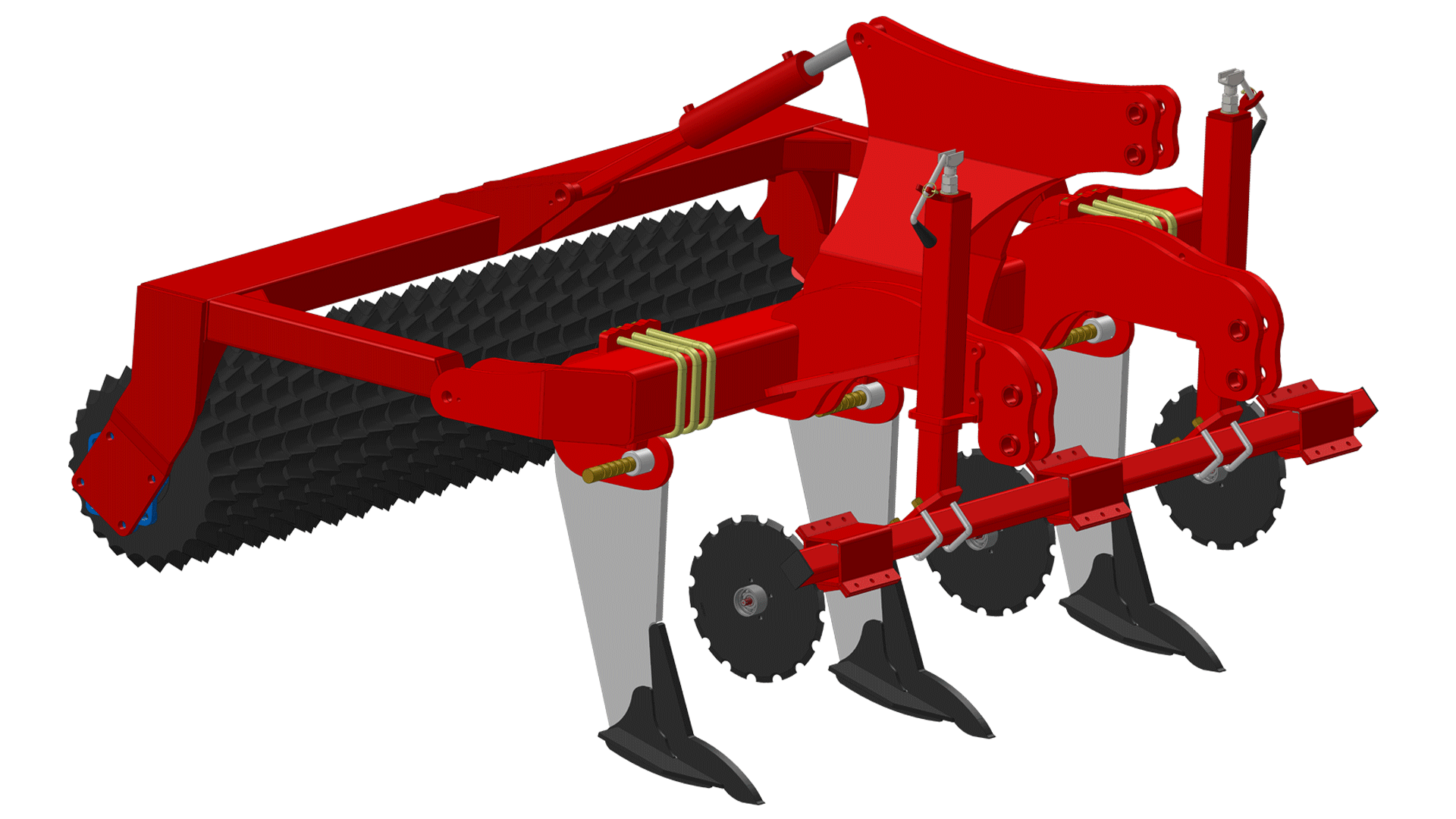

Grass-Tiller

Grass-Tiller is especially suitable for soil loosening in grass fields and for loosing up structural damages from heavy tractors etc.

Efficient subsoiling

This subsoiler has scalloped disc coulters in front of each tine, which cut up the grass effectively, before the tines loosen the soil in depth down to 50 cm. The accu discs ensure that the tines do not rip up the surface and the roller consolidates the soil afterwards.

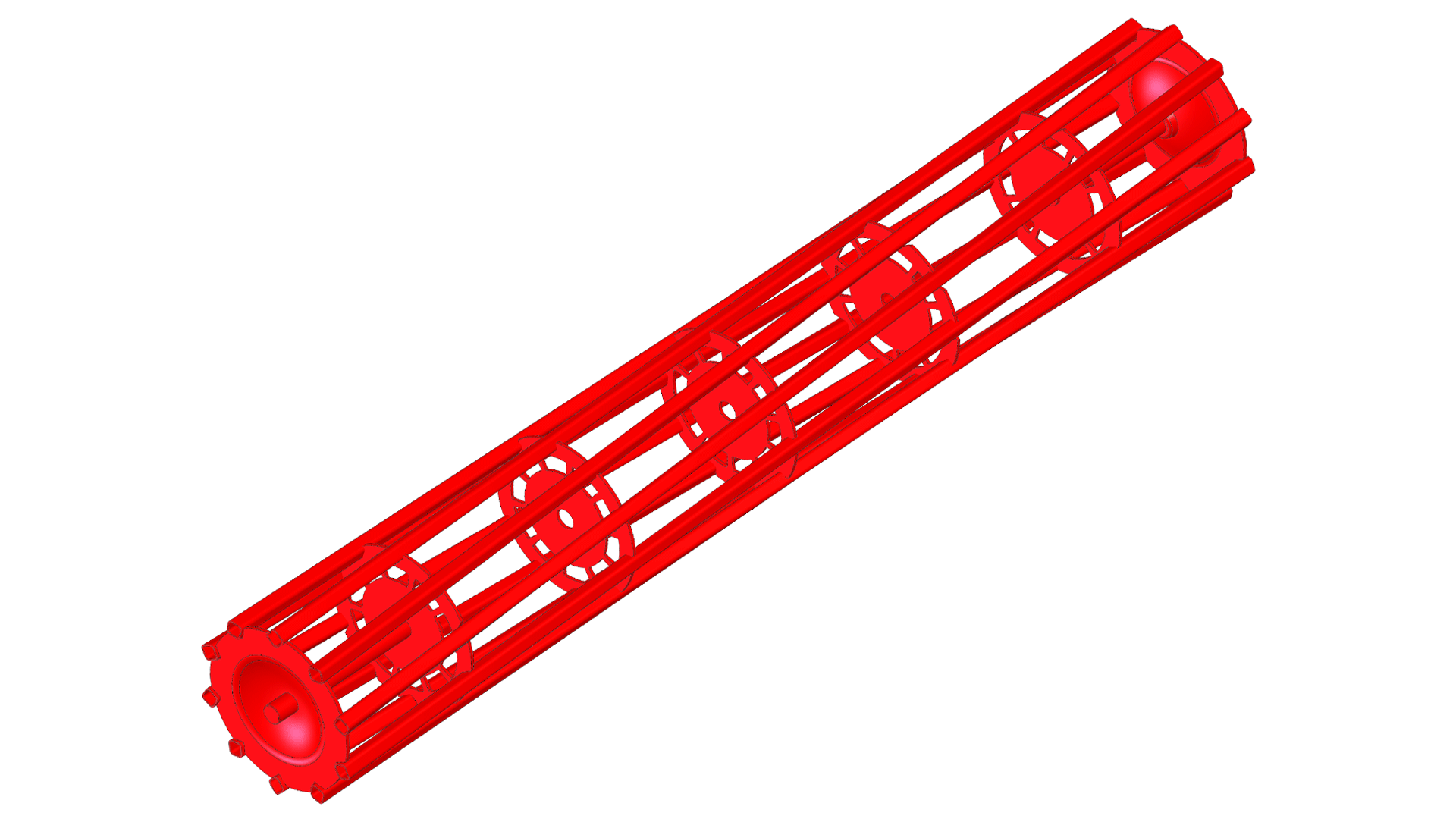

A roller for every need

Divides clods efficiently

A 550 mm square tube roller divides clods on light soil types and ensures good depth control.

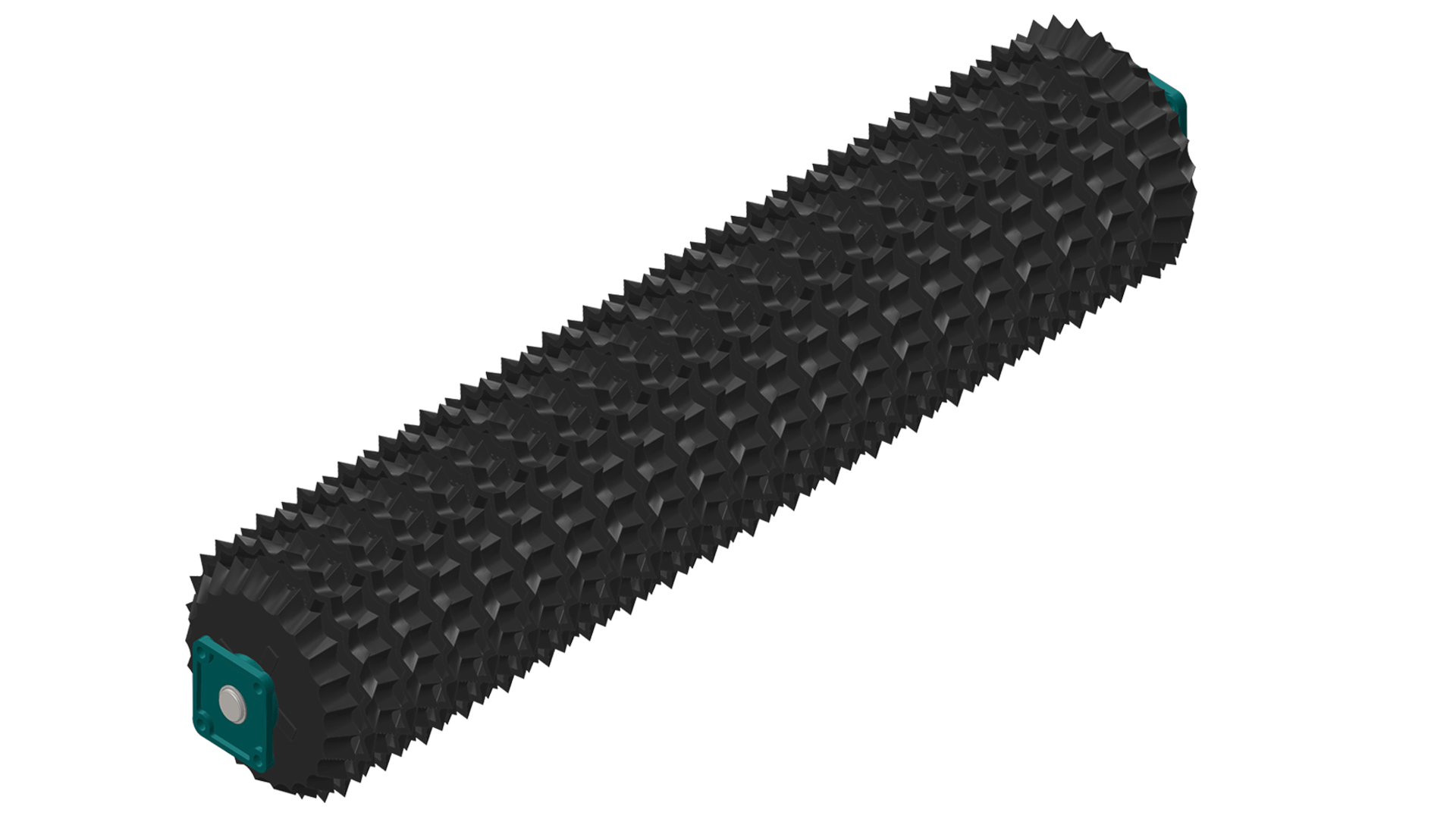

Completely levelled surface

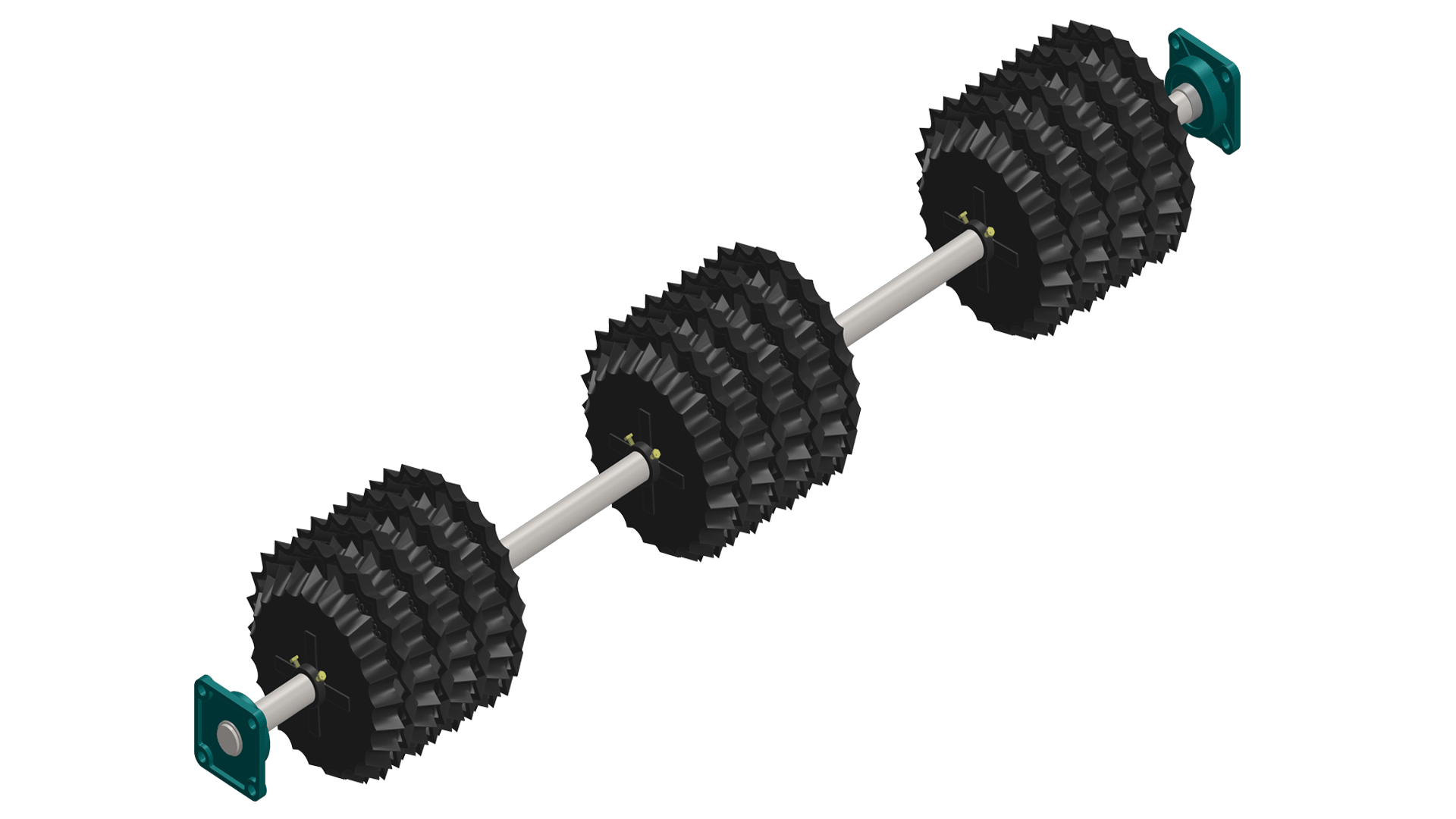

Mounting a Star roller in the entire working width of the machine, the surface is closed after subsoiling. Also, the surface of the grass is slightly aerated, which can affect the grass to set new side shoots. A roller in the entire width of the machine is also an effective way of loosening damages on the surface from spreading manure.

Minimum disruption of the micro-organisms in the soil

With a synchronous Star roller, the surface is left completely closed in the tine tracks, which ensures minimum disruption of the micro organisms in the soil. The weight from the subsoiler is divided into several smaller surfaces hence increasing the pressure compressing the soil harder and efficiently closing the gaps from the tines.

Stone protection for Grass-Tiller

Soil types with many stones

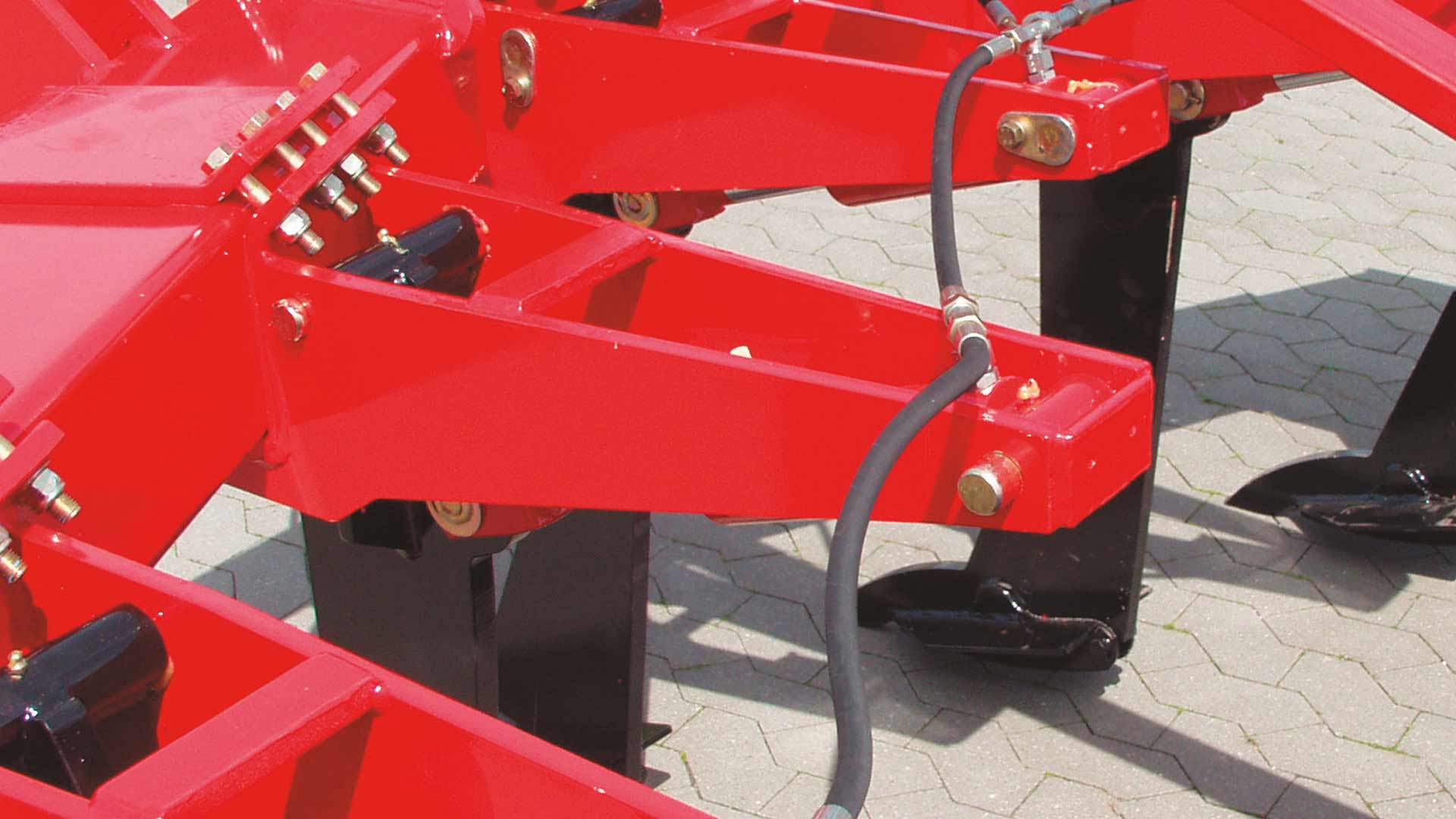

Hydraulic stone protection

A hydraulic stone protection is the best choice, when processing stony soil types. A cylinder on each tine enables the tines to automatically swing upwards, when hitting a stone and down afterwards.

Top soil with no or few stones

Quick-Push stone protection

For top soil and for smaller fields, the Quick-Push stone protecion system is the obvious choice. Once the tine meets a stone, the shearbolt with 8 steps will be cut. The simple procedure of removing the R-clip and pushing the bolt into place again can be done completely without the use of tools and you will quickly be on your way again.